-

- Digital Services

- Google Advertising

- Social Media

- Facebook Marketing

- Search Engine Optimisation (SEO)

- Tik Tok Marketing

- Ecommerce SEO

- Shopify SEO

- Google Advertising Testing

By carefully selecting appropriate keywords associated with your business or product we can help you advertise to your target audience through the use of Google Ads.

Leverage the power of Social Media to your advantage to connect your target audience with your brand, service or product.

Through the power of Facebook we can help you to build brand awareness, grow your online presence, gather leads, and sell your products and services.

Squid's SEO services can help you to improve the quality and increase the quantity of traffic to your website through organic search.

Ecommerce SEO services for your online store. Whether you use Shopify, BigCommerce, Magento or a custom CMS, our SEO experts can help increase online sales.

-

- Creative Services

- SEO

- Web Design

- SilverStripe Websites

- Videography

- E-commerce websites

- Shopify websites

- Web Developer

- Content Marketing

- Brand Design

Squid's SEO services can help you to improve the quality and increase the quantity of traffic to your website through organic search.

Create a website or webpages that not only align with your brand but also create a user-friendly experience.

Use video to grow your business. Our team of creatives and videographers, can script, plan and execute your next video shoot.

E-commerce refers to the selling of physical goods, services or online products over a digital network.

- Event Marketing

-

-

- Projects

- Synthony Regional Tour Poster Design

- Sensory Corner's Facebook Marketing Strategy

- Custom Illustrations & App Development

- Ultimate Ford Video Strategy

- Global Event Marketing | Australia, USA, UK & Europe

- Rivercity Finance | Video Marketing

- Endless Summer's Comprehensive Digital E-Commerce Campaign

- 2023 Waterbourne Management and Promotion

- A Full Automotive Digital Strategy

- T-Shirt Sale E-Commerce Development

- Online Wills & Charitable Trust Animations

- Queenstown House Digital Growth

- Karawhuia Campaign Case Study

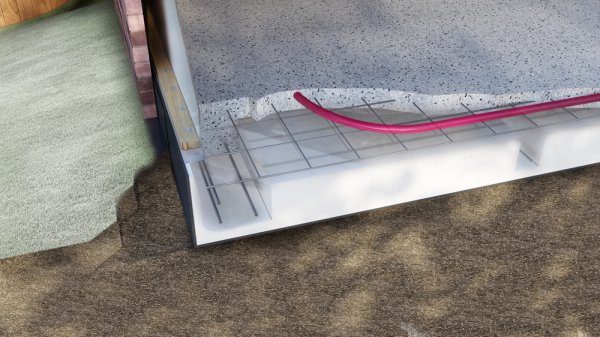

- Design 3D renders with CAD Files

- Shapeshifter New Music Marketing Launch

- Ultimate Mazda Video Shoot

- Queenstown House Digital Marketing Case Study

- NZ Event Digital Marketing | L.A.B Event Marketing

- Redesign of Trustees Executors' Website

- Waterbourne Branding & Event Management

- Vega Full Digital Strategy

- Image Interiors Website Design

- Branding Stellaria to Clay Collective

- Multi-lingual Website Development

- How We Helped Fill a University Course Attendance!

- How We Boosted a Car Dealership's Sales

- How We Helped Shapeshifter Sell Out All Four Shows

Through the use of social media advertising, google advertising, email marketing and SEO we helped to increase online sales by a huge 210%

Trust Motors wanted to have a marketing agency assist with their overall marketing strategy, whilst ensuring what they were doing was building systems to simplify their sales and marketing in house

Working with E-Commerce Businesses is in our range of expertise so when T-Shirt Sale needed some help we knew we could assist.

For Trustees Executors we built two dedicated landing pages alongside some animated assets to explain what each product was.

Karawhiua is a campaign created to help assist whānau, hapū, iwi, and Māori communities in accessing the right information on how to keep safe from Covid -19 and help prevent the spread.

With such a beautiful location, and so many potential collaboration opportunities, we developed a unique strategy to build their online presence.

Our involvement with Waterbourne has been an ongoing project and the results produced are nothing short of the highest quality for both usability and creativity

With very ambitious growth plans, we built a marketing budget for them to ensure it was realistic for these goals, where we built a plan to build a new website to ensure they were getting tangible results across all areas of the business

Image Interiors had a very clear goal in mind and we are happy to have delivered a website within an achievable budget they provided.

- Insights

- Contact

- 0800 A SQUID